I became interested in brick masonry and production while writing an article for the last issue of wear journal, finding out tips of the iceberg of what a mess coal-fired bricks (the standard in China) pose to the environment. Though they are the world’s output leader in this industry, Chinese brick factories are also characterised as one of the least modern industrial sectors in China. Small, village-run production units employing outdated technologies are spread widely throughout the country, and more than 90% of bricks are fired in annular kilns with coal as the predominant fuel, resulting in substantial SO², CO² and other air emissions.

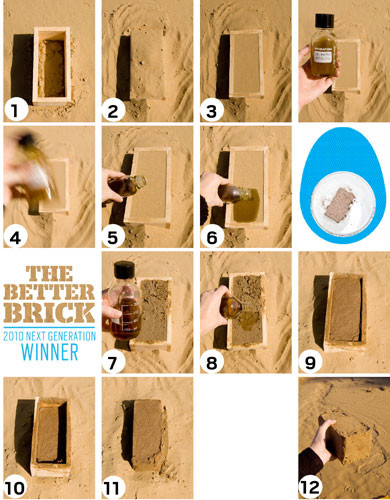

Below is a small (lego-sized) but potentially revolutionary process composed of sand, common bacteria, calcium chloride, and urea (yes, the stuff in your pee)” that could “reduce carbon-dioxide emissions by at least 800 million tons a year.” Read more about these home-grown blocks here.

时间 posted on: 14 May 2010 |

时间 posted on: 14 May 2010 |  发布者 author:

发布者 author:

分类 filed under:

分类 filed under:

May 14th, 2010 - 06:36

[…] This post was mentioned on Twitter by iwish icould. iwish icould said: [家作坊 HomeShop] a better brick: I became interested in brick masonry and production while writing an article for th… http://bit.ly/ctbSbd […]

May 14th, 2010 - 08:50

homo generator.

May 14th, 2010 - 11:47

eh? please elaborate…

May 14th, 2010 - 22:26

a very artful engagement of our own technological being, combining “nature” with “animals” with “human waste” with “capital” in such a way as we slow down the process of killing ourselves (or increase profitability, which amounts to much the same thing when you factor in the true costs of environmental devastation … admittedly something contemporary capitalism doesn’t do very well today).

September 30th, 2010 - 06:52

http://www.brickstainable.com/competition.html

February 7th, 2012 - 22:22

mudbricks elsewhere: http://www.youtube.com/watch?v=aCdhyvKzk9c